PLATINODE® EGL: Anodes for galvanizing lines

Strip galvanizing lines are specialized in providing steel strips with a protective zinc coating. Galvanized steel strips are used in many industries, including the automotive, construction and household appliance industries. An essential component of these strip galvanizing lines are the anodes. These are needed to enable the electrochemical process of galvanizing. Insoluble anodes are used to ensure an even zinc coating on the strips.

Find out more about our anodes and how they help to improve product quality and durability!

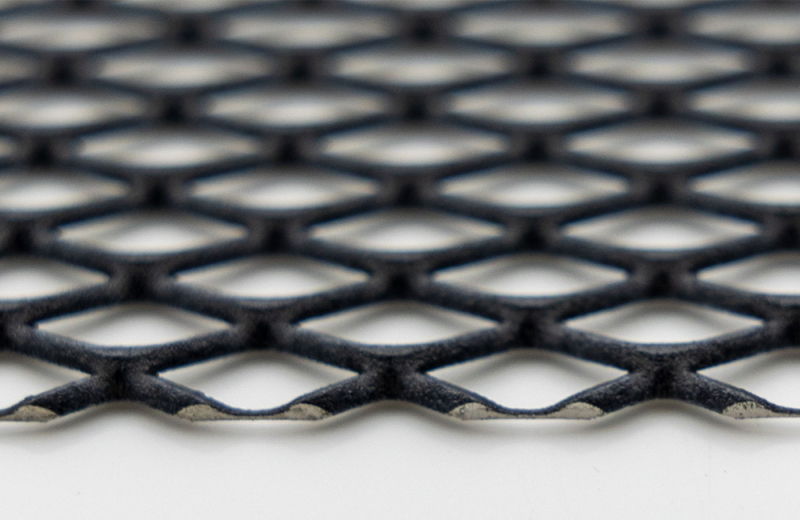

MMO anodes (mix-metal-oxide anodes) consist of a titanium substrate plated with several layers of noble metal oxides. They are characterized by high conductivity, corrosion resistance and long service life. These anodes are used in electrochemical processes such as strip galvanizing, in which steel is coated with a protective zinc layer.

Advantages of MMO Anodes

- Longevity

The robust oxide coating ensures an exceptionally long service life and high corrosion resistance. - Efficient power distribution

MMO anodes provide even current distribution, resulting in a uniform zinc or zinc/nickel plating on the steel. - Low maintenance

They require less frequent replacement and maintenance, which significantly reduces operating costs.

- High current density

MMO anodes are optimal for applications with high current densities, such as those found in galvanizing lines. - Environmentally friendly

Since they are not consumed, MMO anodes do not produce any waste and are environmentally friendly.

In addition to MMO anodes, platinized titanium anodes are another option that has been successfully used in strip galvanizing applications. These anodes consist of a titanium substrate with a platinum coating. Platinized titanium anodes are a costeffective alternative to the established MMO anodes at current precious metal prices.

Advantages of platinized titanium anodes

- High corrosion resistance

Platinum offers excellent corrosion resistance, especially in aggressive environments. - Efficient power transmission

The platinum coating ensures very efficient current conduction, similar to MMO anodes.

- Long service life

With appropriate maintenance, platinized titanium anodes can have a long service life. - Suitable for high-current applications

Like MMO anodes, platinized titanium anodes are also excellent for applications with high current densities.

Comparison with soluble anodes (e.g. zinc anodes)

MMO- and platinized titanium anodes

Soluble anodes

Lifetime and durability

Both anode types offer a long service life and high corrosion resistance due to their good electrocatalytic properties and their resistance in chemical solutions.

These are consumed in the process and must be replaced regularly, which increases operating costs. Fluctuations in electrolyte concentration and pH regulation can lead to inconsistent coating quality.

Power distribution and efficiency

Both anodes ensure even current distribution and stable performance, resulting in a uniform zinc coating.

Over time, the current distribution can become uneven due to the processing of the zinc anodes, which can cause quality problems.

Maintenance effort

Both require no maintenance, as their insoluble nature means that there is no short-term precious metal erosion.

Require regular replacement and refilling, which increases maintenance costs.

Material consumption and environmental aspects

No material consumption, less waste and no need to dispose of hazardous residues. MMO anodes can be recoated several times and residual coatings containing iridium can be recycled.

Continuous material consumption leads to more waste, which must be disposed of properly.

Application areas

- Strip galvanizing

- Electrolytic plating

- Corrosion protection systems

Conclusion

MMO and platinized titanium anodes offer long-lasting, efficient and environmentally friendly solutions for galvanizing lines. However, due to the high iridium market price, the cost pressure on users is enormous. Here, platinized titanium anodes represent a more cost-effective alternative.

Both anode types ensure even current distribution, are low-maintenance and costefficient in the long term, making them the optimal choice for modern galvanizing processes.

Christian Kurrle

Sales Electrocatalytic Electrodes

christian.kurrle@eu.umicore.com

Teams Chat starten

+49 7171 607 167 (Office)

+49 157 8053 5100 (Mobile)

Website content matching this page