Time is running out for lead anodes - EU sets strict limits for lead exposure in the workplace

In the European Union, regulations have been in place since 1982 to limit lead exposure in the workplace. The reason for this has long been known: prolonged exposure to lead damages the nervous system, kidneys, heart and blood. In addition, lead in the body has been shown to impair fertility and foetal development.

For the first time in 40 years, the EU has now reviewed the limit values for lead exposure in the workplace and lowered them by a factor of five. Member States now have two years to implement the new limits in their national legislation.

We recommend that you use this time to switch to a lead-free coating process by replacing lead anodes 1:1 with our PLATINODE® - this would make the new limits irrelevant for your company.

New limits are strict and must be reached by 2028

By lowering the limit values for lead and its inorganic compounds in the workplace, the legislator is improving the protection of workers from the dangers of occupational exposure. This step follows the latest scientific and technical findings, which indicate that significantly lower limit values are required to protect workers' health more effectively, particularly with regard to reproductive toxicity.

The new directive will lower the limit values for lead as follows (see also the European Union publications opposite), which will be binding for all employers, including those in the electroplating industry, by the end of 2028:

In order to protect newborn babies from the proven reproductive toxicity of lead, the previously permitted biological value for female employees of childbearing age will be reduced by a factor of around 15 - to 4.5 μg/100 ml.

As workplaces cannot be designed differently for all genders and age groups, the legislator is thus prescribing significantly stricter limit values in many cases - through the back door, so to speak.

Lead anodes in electroplating are now finally counted out

The use of lead anodes in electroplating can release lead particles and vapours that can cause lead poisoning if inhaled or come into contact with the skin. For this reason, electroplating companies are also subject to the new EU directives in order to prevent lead poisoning and thus serious health consequences.

Lead / lead chromate

The health and safety risks associated with the use of lead anodes are only one side of the coin. The waste materials produced by lead anodes, such as lead chromate in hard chrome plating, harbour similar risks and are, above all, ecologically very questionable and correspondingly costly to dispose of.

However, it is not only health and safety aspects that have always spoken against the use of lead anodes. The comparatively short-lived lead anodes are also extremely questionable from an ecological point of view when it comes to disposal. According to the 2015 World’s Worst Pollution Problems Report, lead is considered the environmental toxin with the most devastating effects on the environment and humans.

This assessment is resulting in ever stricter regulation of lead processing companies worldwide. The EU's currently revised limit values are just another piece of the puzzle. The long-term goal of all measures is to largely eliminate lead from industrial use through concerted global efforts.

Platinised anodes are superior to lead anodes in all respects

Our platinised anodes enable you to use a lead-free coating process that sets new standards for health and safety in your company.

This benefits not only the employees, but also the company. For example, the costs of monitoring lead exposure in the workplace, medical monitoring of staff and the purchase and maintenance of special protective equipment are eliminated.

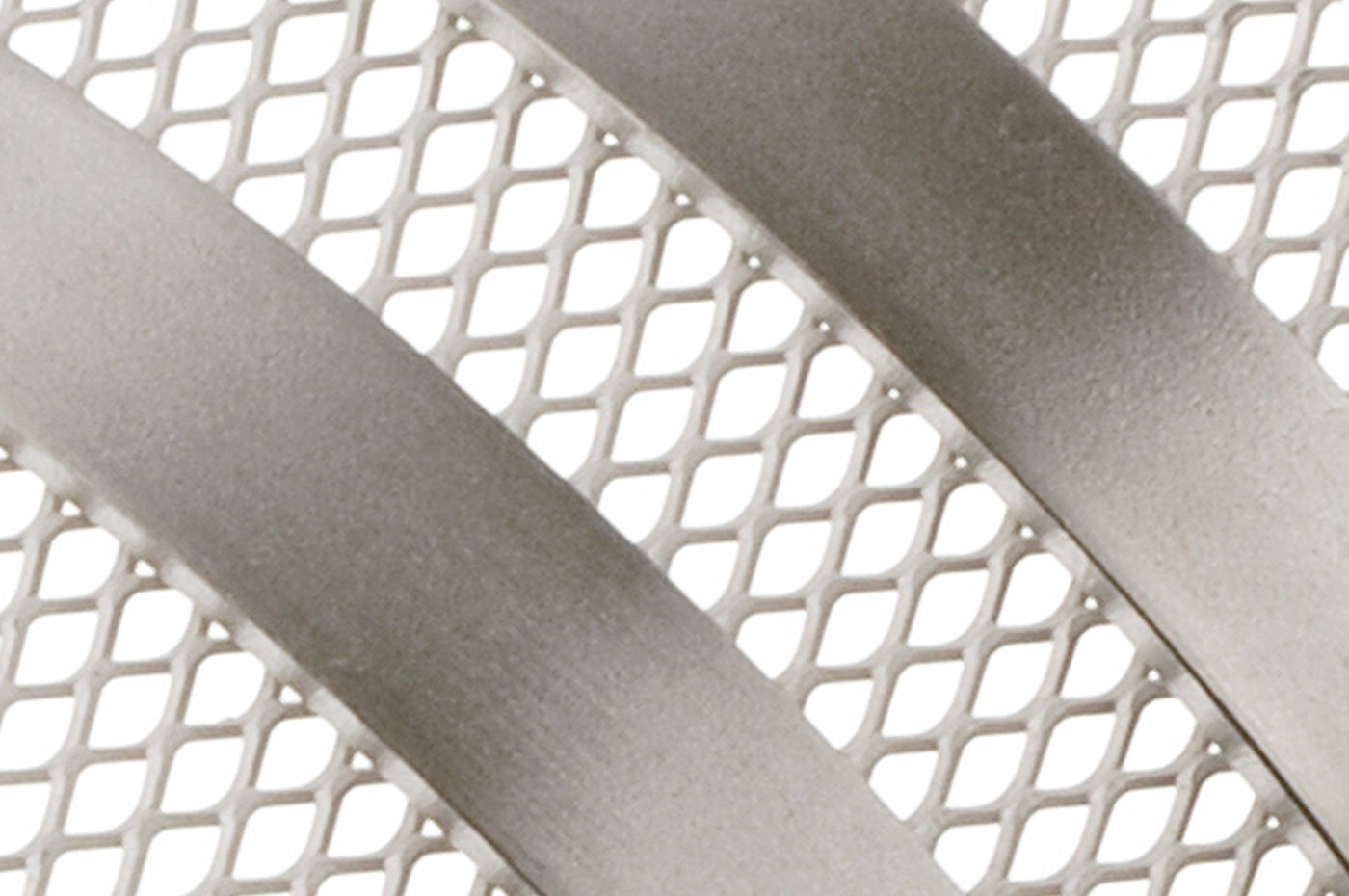

PLATINODE®

Thanks to the platinum functional layer made from a cyanide salt melt, our dimensionally stable electrodes (anodes and cathodes) have excellent adhesive strength in addition to high ductility and maximum purity. This makes it possible to produce layers with high platinum thickness, maximum corrosion resistance and an excellent durability.

PLATINODE® also offers a number of other advantages. In terms of quality, you benefit from an outstanding coating quality and, in terms of external presentation, from a significantly more ecological reputation - not only through a lead-free production process, but also through lower energy requirements and thus a corresponding reduction in CO2.

PLATINODE® also offers a whole range of economic benefits: Eliminated disposal costs, lower energy, maintenance and production downtime costs - and, in the medium term, lower procurement costs thanks to the possibility of replating the customised anode design.

Take the step with us towards a future-proof and sustainable coating process

Of course, every change involves effort. Thanks to our experience, even with large-scale production landscapes, we reduce this effort and also the time investment for you to an absolute minimum.

Now is the time to at least think about a lead-free and regulation-free coating process. We will be happy to support you with comprehensive advice and a customised profitability calculation, including suitable subsidy options.

Christian Kurrle

Sales Electrocatalytic Electrodes

christian.kurrle@eu.umicore.com

Teams Chat starten

+49 7171 607 167 (Office)

+49 157 8053 5100 (Mobile)

Website content matching this page