Umicore MDS expands into the semiconductor market

We are expanding our product offering in the growing market of semiconductors with the earlier bolt-on acquisition of our Chinese partner Shinhao Materials LLC. Shinhao focuses on copper plating in the advanced packaging sector.

We and Shinhao partnered in 2019 combining Shinhao's technical know-how and intellectual property in copper additives under the IntraCu® product line with our global infrastructure and track record as a responsible high-quality materials technology supplier.

With our subsidiary Umicore Suzhou Semiconductor Materials Co., Ltd (USSM), which emerged from the acquisition, we have now finally accomplished this.

Click here for the Chinese version.

Click here for the Chinese version.

(Redirect to the Chinese website of the Umicore Group)

For us, the subsidiary USSM and the modular additive system IntraCu® are integral parts of our strategy of establishing our presence in the semiconductor materials deposition market.

We are accelerating steps of entering this segment, which we have been preparing for years, without abandoning our existing business areas, of course. This is not a shift in our business model, but rather a strategic expansion that builds upon the know-how we have built-up over decades.

Michael Herkommer (Vice President)

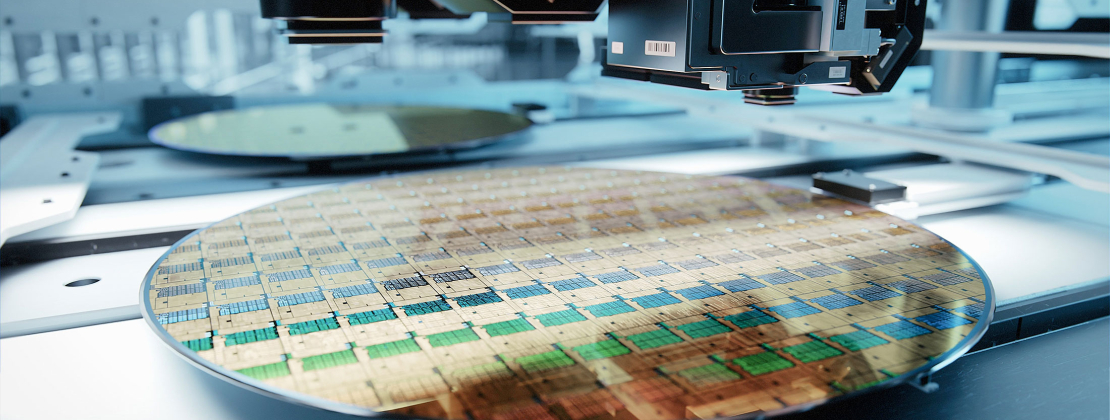

Semiconductor customers can expect a comprehensive range of innovative and patent protected products in the electroplating field for ECD (additives, VMS, cathode contacts, anode materials, etc.). The new USSM headquarter (in Wujiang, near Suzhou) offers ideal conditions for R&D over more than 1,000 square meters. At the center of the site are class 6 clean rooms according to DIN EN ISO which ensure high standards for error-free production processes.

Synergies with 'Thin Film Products'

The new site also features modern, bright office spaces and a connected warehouse, so that the local team can quickly respond to customer’s inquiries, product qualifications, troubleshooting and after sales services. Initially, 15 highly qualified specialists are employed with further expansions already planned. In addition to the existing research and production sites in Liechtenstein and Taiwan that are specialized in evaporation materials and sputter targets, the new site in Suzhou performs as fully fledged hub for products related to vacuum deposition technologies.

New product IntraCu® as a 'game changer'

IntraCu® is a patented additive system that exhibits the potential to exceed the ever increasing requirements of semiconductor advanced packaging customers in terms of quality, cost efficiency and reliability. The IntraCu® additive system ensures material properties and crystal structures that eliminate typical limitations in semiconductor production. For example, IntraCu® nanograined copper is recognized by the industry as a potential ‘technology enabler’.

Among other things, IntraCu® enables low-temperature copper-to-copper hybrid bonding and proliferation of the chiplet technology.

Another case is its use in low-stress or stress-free copper interconnections to reduce warpage experienced in silicon, organic or glass substrates.

Dr Yun Zhang (Strategic Technology Adviser)

Another key advantage of IntraCu® is the increased reliability of integrated circuits (ICs). This results in less production waste and a significantly longer lifespan for the ICs. To ensure and further optimize the desired effects, we already working with world-leading technology companies and top customers in the industriy. These collaborations should also continue to benefit from the ease of use of IntraCu® – the additives require no additional processing steps and are compatible with standard equipment, making the use of IntraCu® even more attractive.

We will significantly increase our visibility in the industry

Global demand for semiconductors is growing steadily, driven by artificial intelligence, further digitalization and higher demand for advanced packaging from industries such as automotive, telecommunications and consumer electronics. IntraCu® is expected to benefit from applications in artificial intelligence (AI) and in display substrate applications and will also be manufactured at MDS’s site in Germany to meet demand in Europe and the United States.

‘We know that we are still a relative unknown in the semiconductor market. That is precisely why this expansion was so important: together with our existing presence in the thin film product market, it will significantly increase our visibility in the industry,’ says Dr Klaus Leyendecker, our Senior Division Manager Semiconductors. He expects revenues of our semiconductor segment to grow by 50% by 2027.

Dr Leyendecker sees the reason for this significant increase in such a short time in the establishment of IntraCu® and thus of Umicore MDS on the market.

Our products in this segment are outstanding, but they are still largely unknown. I see IntraCu® as a game changer and door opener for applications in the booming AI field but also for fast-changing sectors such as display substrate applications.

Dr Klaus Leyendecker (Senior Division Manager Semiconductors)

Equally, in the medium term, IntraCu® will also be manufactured and available, e.g. from our site in Germany in which the “copy-exact infrastructure” has already been created to be able to meet both additional demand from Europe and the USA and also the expected business continuity and backup in the global supply chain.

With the founding of USSM, we demonstrae our commitment to continuously developing innovative solutions for the semiconductor industry. We will leverage the synergies between our global infrastructure, broad product offering, expertise and local customer focus to respond quickly to market changes and customer needs. This is the cornerstone for us to play an important long-term role in this rapidly changing industry.

Impressions of the opening, the equipment and the headquarters

Michael Herkommer (Vice President), Dick Ng (Head of Sales USSM), Dr Yun Zang (Strategic Technology Advisor USSM) and Dr Klaus Leyendecker (Division Manager Semiconductor Applications) at the official opening ceremony of the subsidiary Umicore Suzhao Semiconductor Materials Co., Ltd. (USSM) in Suzhou, China.

Michael Herkommer emphasises in front of employees and media representatives at the opening ceremony, directly in front of the modern building (right), that he has been looking forward to this day for many years.

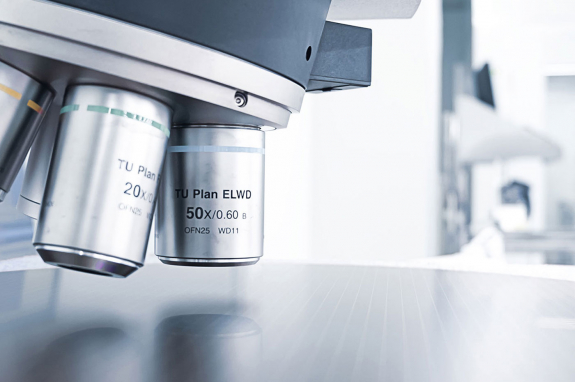

Modern equipment, such as this scanning electron microscope for material processing and sample preparation on the nanoscale, enables high-level imaging and analysis of our product performance.

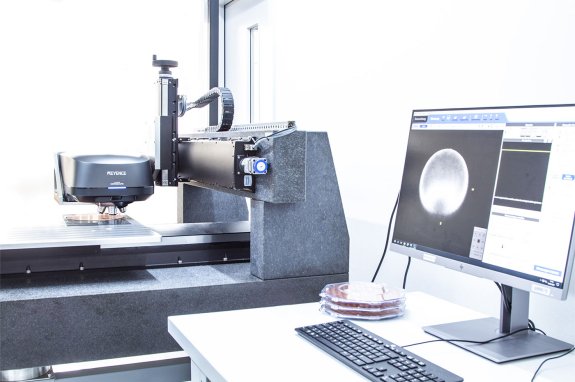

Laser microscopes at the site prove that the IntraCu® additive system provides material properties and crystal structures that eliminate typical limitations in semiconductor production.

The new USSM headquarter offers ideal conditions for R&D over more than 1,000 square meters.

At the center of the site are class 6 clean rooms according to DIN EN ISO which ensure high standards for error-free production processes.

Dr. Klaus Leyendecker

Division Manager Semiconductor Applications

klaus.leyendecker@eu.umicore.com

Start Teams Chat

+49 7171 607 223 (Office)

+49 1704 8340 79 (Mobile)

Website content matching this page