State subsidy for PLATINODE® HC - lead anodes in hard chrome plating are deprived of economic advantage

With our PLATINODE® HC platinised titanium or niobium anode, which was specially developed for hard chrome processes and is manufactured using the highest-quality of all electrocatalytic coating processes (high-temperature electrolysis), significant energy savings are possible compared to lead anodes. Within the framework of the European Green Deal, which among other things provides for a significant reduction in energy consumption and thus in CO2 emissions, it is thus considered eligible for subsidies.

This would reduce the investment costs for the high-quality, long-lasting electrode, which is in any case more economical in the medium term than lead anodes, by up to 60 % if the energy savings are included - and without any additional expense for our customers. We offer the application for the subsidy in Germany as a free service and are working flat out to offer this service in all other relevant European countries as well.

Government subsidies for PLATINODE® HC in Europe

The European Commission has set itself the goal of making Europe the first climate-neutral continent by 2050. To this end, the European Green Deal was launched, which includes as an essential component the reduction of energy consumption, as is possible with PLATINODE® HC in hard chromium plating. The subsidies provided for this can be applied for at the respective country-specific institutions.

In Germany, for example, up to 50 % of the investment in PLATINODE® HC can be subsidised by the Federal Office of Economics and Export Control (BAFA) up to a maximum of € 15 million. The decisive factor for the subsidy is the avoided CO2 emissions due to a lower energy requirement of at least 30 % compared to lead anodes. Corporations can reduce their investment sum here by 500 €, medium-sized companies by 900 € and small companies even 1200 € per tonne of CO2.

We take care of the application for you

If you wish, we can take care of the application for the state subsidy for you. This service is advantageous for you in three ways:

- We take care of the written application for the subsidy, which means that you do not have to spend time reading and applying

- We will put you in touch with an independent energy consultant who specialises in the application process

- We provide you with the necessary confirmation of CO2 savings through an official verification procedure

Advantages in terms of sustainability

It is not only for monetary reasons that the future belongs to platinised electrodes. The focus on a sustainable production chain is increasingly causing purchasing companies to sort out suppliers that do not fit into their concept.

The reason for this is the lead chromate produced during hard chrome plating, which is ecologically classified as "highly hazardous to water" (highest possible classification) in Germany. In addition, the waste product is classified as carcinogenic and toxic to reproduction. The European Chemicals Agency ECHA has included lead chromate in the candidate list of substances of very high concern.

Energy savings of over 30 %

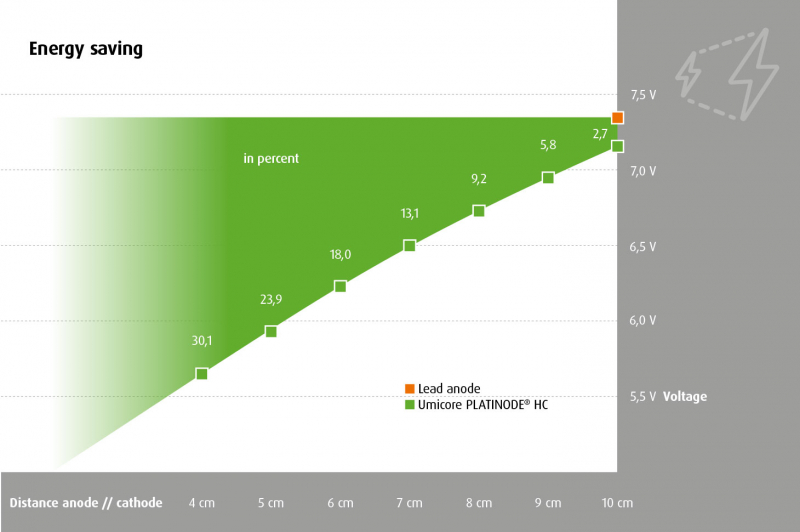

The independent engineering firm Delta Engineering & Chemistry carried out a comparative analysis under laboratory conditions. It was found that a 1:1 replacement of lead anodes with the better conducting PLATINODE® HC enables energy savings of at least 2.7 %. In practice, we are already experiencing actual savings of around 12 % through pure replacement.

The engineering office confirms a reduction in energy consumption of over 30 % when taking advantage of the flexible shape and stability of PLATINODE® HC. In contrast to conventional lead anodes, the distance between anode and cathode can be significantly reduced, which makes the required energy input decrease almost linearly.

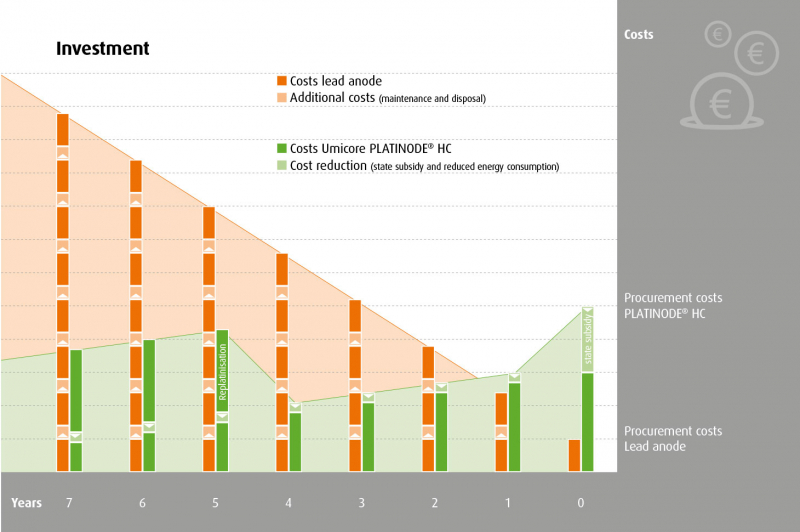

Already more economical in the 2nd year

Basically, PLATINODE® in all versions has a high adhesive strength, corrosion resistance and ductility and thus an above-average service life of 5 years - while commercially available lead anodes can only be used for about one year. In the case of energy-intensive hard chrome plating, the PLATINODE® HC usually pays for itself in the second year due to the possible government subsidy, the energy savings and the elimination of lead chromate disposal.

The reusability of the individually manufactured electrode design, which can be replatinated after the platinum layer wears off, also makes the PLATINODE® HC the more sustainable and cost-efficient solution in the long term.

Wilhelm Bauer GmbH & Co.KG is a renowned company that has specialised in the finishing of metallic surfaces since 1945. A few years ago, the company decided to replace the lead anodes in a small hard chrome bath with a PLATINODE® HC custom-made by us.

The experience with the platinised titanium anodes was very positive and the savings of around 10 % in energy costs as well as our correspondingly more positive CO2 balance speak for themselves.

Jan Bauer (Managing Director Wilhelm Bauer GmbH & Co.KG)

As energy costs have risen steadily in recent years, the decision was made in 2022 to also retrofit the much larger bathrooms. At the beginning of 2023, the first 24 customised anodes with an impressive length of over 6 metres were installed and production was successfully started. Equally impressive are the following figures for the replacement stage (which is expected to refinance itself to around 36 % through energy savings and subsidies):

The investment costs of PLATINODE® HC are higher than those of conventional lead anodes. However, the amount should be viewed relatively and only compared after 5 years (average service life of the PLATINODE® HC) with the lead anodes that have to be replaced approximately every year.

Calculate here your probable state subsidy and saved electricity costs over the 5 years - you may mentally deduct the total amount directly from our offer for the PLATINODE® HC. Don't be surprised if you would be significantly more economical than with the previous use of lead anodes.

Your data input

| Power consumption | kWh / Year |

| Electricity price per kWh | Euro |

Your results per year

| Energy costs | Euro |

| CO2 emissions caused | Tons |

Your savings when using PLATINODE® HC*

using the example of the subsidy for Germany based on your information above

Energy and CO2

| Energy cost savings per year |

Euro |

|

CO2 savings |

Tons |

State subsidies

| small companies |

Euro |

| medium-sized companies |

Euro |

| groups | Euro |

The amount results from the state subsidy and the presumed energy savings over the average lifetime of the PLATINODE® HC for small companies Euro or Euro for medium-sized companies or Euro for corporate groups

Advice and technical service right from the start

Are you interested in our PLATINODE® HC and the associated service? Then let's talk about it. To clarify all relevant details, we offer you a comprehensive consultation in advance – in a personal conversation, we will also be happy to inform you about other state subsidies (for example, for conversion measures and lead disposal). On this basis, we will be happy to prepare a quotation for you. This also includes a profitability calculation. On this basis, you should be able to make a well-founded decision for or against our solutions.

Of course, we are also there for you after the successful commissioning, if necessary also on site worldwide.

Christian Kurrle

Sales Electrocatalytic Electrodes

christian.kurrle@eu.umicore.com

Start Teams Chat

+49 7171 607 167 (Office)

+49 157 8053 5100 (Mobile)

* Conservative sample calculation based on practical experience. Your savings and thus the investment reduction may be higher or lower.

Calculation basis

- 434 g CO2 emission per kWh according to current electricity mix in Germany 2022 (www.umweltbundesamt.de)

- 30 % energy saving by switching to PLATINODE® HC and thus a possible 60 % reduction in the distance between anode and cathode

- Investment reductions are calculated for the average lifetime of the PLATINODE® HC (5 years)

Website content matching this page