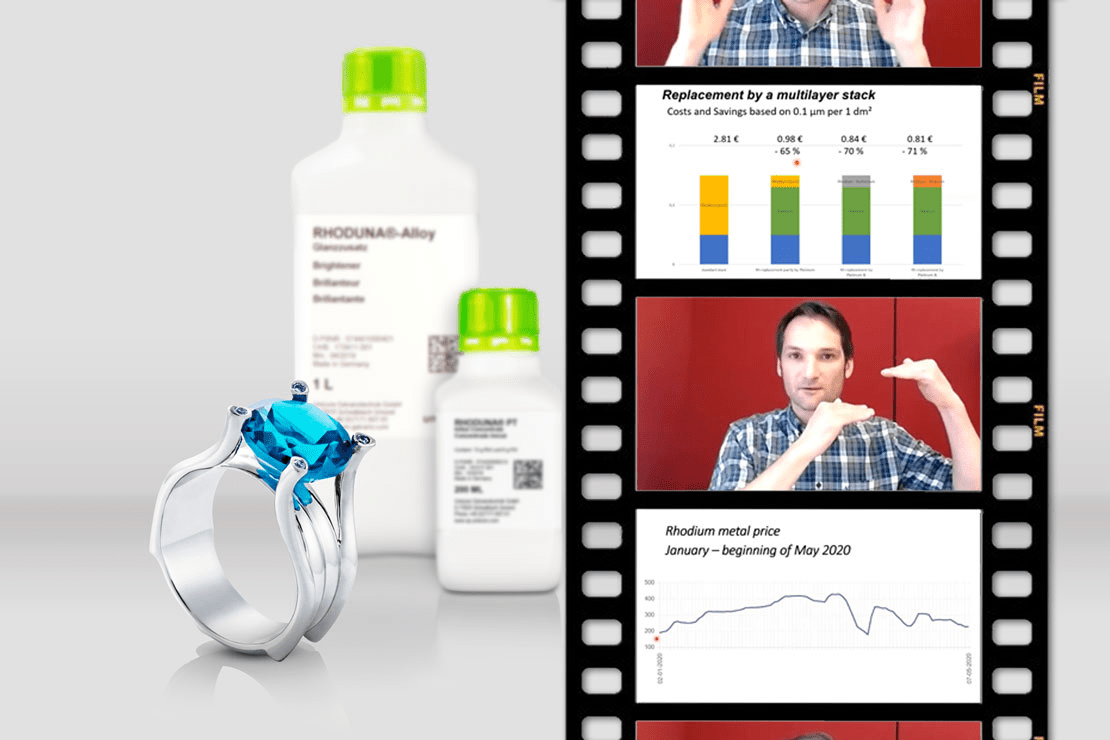

Our expert shows cost-saving techniques for rhodium surfaces

The market prices of precious metals, especially in the processing of rhodium, are forcing us to reconsider its use as a final layer. In a webinar conducted by GemAtlas Joachim Grimm shows possibilities to save costs by replacing palladium and/or rhodium layers.

Umicore alloys are convincing both

for price and quality

Despite the obvious economic advantages of switching from pure precious metals to an alloy, many producers are reluctant to make the change. This is unjustified if you skim the coating and electrolyte properties of, for example, our sophisticated RHODUNA® Alloy Electrolyte range. On top of this, we have often been able to combine the advantages of two precious metals through intensive research work. In addition, even a trained eye cannot tell the difference to a pure rhodium layer.

In the current price constellation, savings of up to 50 % are possible compared to pure rhodium electrolytes. It is therefore worth taking a closer look at the price advantages of our processes. For this purpose we have set up a website to give you clarity at a glance.

An individual price calculation will show you how an introduction or changeover can impact your specific economic case. We can also make a quality analysis by examining technical details with you.

Consulting and technical service right from the start

We look forward to hearing from you.

Markus Legeler

Manager Sales International

Email: markus.legeler@eu.umicore.com

Phone: +49 7171 607 204

Fax: +49 7171 607 316