Service Electrocatalytic Electrodes

Our PLATINODE® electrodes are coated with pure platinum in a cyanide salt melt. This manufacturing process guarantees maximum quality and service life.

Under this brand name, we also offer dimensionally stable mixed metal oxide anodes (MMO) with an optimal price-performance ratio.

Product consultation

Our comprehensive product consulting offers you tailor-made solutions for your specific requirements. We support you with the following services:

- Free consultation: We help you select the optimal electrode system for your application to ensure maximum efficiency and performance.

- Profitability calculations: Our experts provide you with sound decision-making support for investments and check possible government subsidies to optimize your costs.

- Supported conversion: We support you in the conversion to alternative, dimensionally stable anode systems and ensure a smooth transition.

- Production of customized sample anodes: We develop and supply tailor-made sample anodes that are precisely tailored to your needs.

- Individual customer training: Our training courses provide you with the necessary know-how and background knowledge to exploit the full potential of your electrocatalytic electrodes.

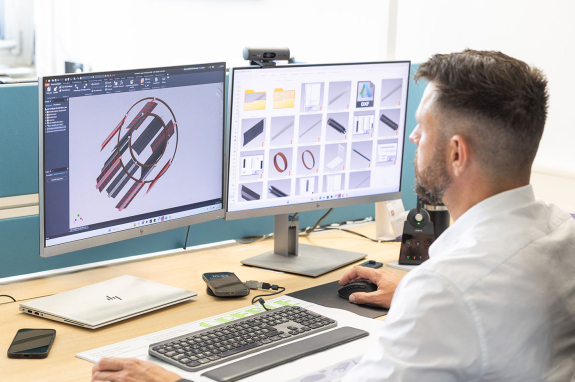

Customized design and construction

Our customized design and construction enable us to provide tailor-made solutions for your specific requirements. We support you with the following services:

- Assessment of the current situation: We record process parameters, dimensions, and geometries directly at your site in order to create a customized electrode system concept.

- Design, dimensioning, and calculation: Our experts take care of the precise design, dimensioning, and calculation of your electrode constructions to ensure optimum performance and efficiency.

- Tailor-made offers: We prepare detailed offers that are precisely tailored to your needs, including CAD-supported drawing creation.

After Sales Service

Our comprehensive after-sales service ensures that your electric catalyst electrodes always function optimally and your processes remain efficient.

- Regular wear inspections: We carry out regular inspections of the electrodes to determine their service life in the customer's process and to ensure scheduled and preventive inspections.

- Troubleshooting and fault analysis: In the event of anode-related process problems, we offer rapid fault analysis and troubleshooting to identify and rectify problems.

- Service life analyses and benchmark tests: Our experts carry out service life analyses and benchmark tests in your processes to evaluate the performance of the electrodes.

- Customer training: We train your employees in the handling and maintenance of the electrode systems to ensure optimal use and maintenance.

- Fail-resistant: We develop a fail-resistant concept including delivery and maintenance agreements to provide continuous support for your processes.

Reuse and recycling

Our services in the field of electrocatalytic electrodes include comprehensive reprocessing, repair, refinement, and recycling to ensure sustainable use of resources. Below you will find the key aspects of our services:

- Analysis of the remaining precious metal: We carry out a detailed analysis of the remaining precious metal on used electrodes. This enables us to determine the exact value of the precious metals and maximize the efficiency of the reprocessing.

- Reprocessing of electrode structures: Our experts carefully rework the structures of the electrodes. This includes repairing and replacing damaged parts to restore the performance of the electrodes.

- Resource-saving reprocessing: We attach great importance to resource-saving work. Wherever possible, we reuse materials to minimize the consumption of new resources and reduce our environmental impact.

- Recoating: After reprocessing, the electrodes are recoated to extend their functionality and service life. Our high-quality coating processes ensure that the electrodes meet the highest standards.

- Precious metal credits: Customers who send their used electrodes to us for reprocessing receive precious metal credits. These are based on the quantity and value of the remaining precious metal.

- Closed loop: Our closed-loop approach ensures that all materials and resources are kept in the cycle. This promotes sustainability and reduces waste by continuously reusing valuable materials.

Development of electrocatalytic electrodes

Application-specific further development is also part of our services in the field of electrocatalytic electrodes. We work closely with our customers and many renowned electrolyte suppliers worldwide to develop customized solutions.

- Customer-oriented further development: We value cooperation with our customers in order to understand and implement their specific requirements and wishes. This close cooperation enables us to develop customized solutions that are optimally tailored to the respective applications.

- Partnerships with leading electrolyte suppliers: Our partnerships with all well-known electrolyte suppliers worldwide enable us to always use the latest and best materials. This cooperation ensures that our electrodes meet the highest quality standards and are always state-of-the-art.

- Cooperation with institutes and universities: We work closely with leading institutes and universities. With our products and expertise, we support new developments in the field of electrochemistry.

Website content matching this page