NiRUNA® 6460 Nickel Electrolyte

NiRUNA® 6460 Nickel Electrolyte

Weakly acidic nickel electrolyte without boric acid in high-speed applications

NiRUNA® 6460 is a high-speed nickel sulphamate electrolyte in which the use of boric acid has been deliberately avoided. According to the European CLP regulation, boric acid is classified as toxic and harmful to health. Instead of boric acid, an innovative liquid buffer system is used as an alternative, which also means a lower health risk for the system operator. Necessary electrolyte additions can be made during operation without any major time expenditure, as the laborious pre-dissolution of the conventional buffer salt is no longer necessary.

The electrolyte does not have to be heated during downtimes, which means lower energy requirements and a cost advantage compared to processes containing boric acid. There is no crystallization of electrolyte components at room temperature.

NiRUNA® 6460 is particularly suitable for use in high-performance systems, e.g. for selective coating or for continuously operating belt systems.

The composition of NiRUNA® 6460 enables the deposition of fine-grained, silk-matt or shine-retaining coatings with low internal voltages even at high current densities and corresponding deposition speeds.

The NiRUNA® 6460 Wetting Agent NF is used to prevent pores and the NiRUNA® 6460 Grain Refiner to increase the basic shine or grain refinement. Furthermore, residual stresses in the nickel layer can be reduced by adding the grain refiner.

Advantages

- Boric acid-free electrolyte with innovative liquid buffer system

- Lower hazard potential and health risk for system operators

- Electrolyte replenishment possible during operation

- No need to heat the electrolyte during downtimes

- Cost advantage due to reduced energy requirements

- No crystallization of the electrolyte at room temperature

- pH-stable / large pH operating range

- Ductile, low-porosity coatings with good corrosion resistance

Applications

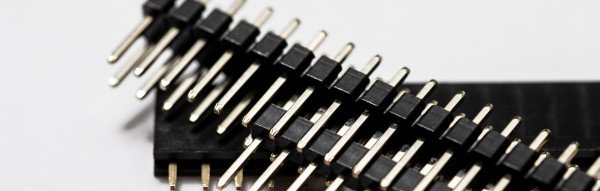

- Connectors

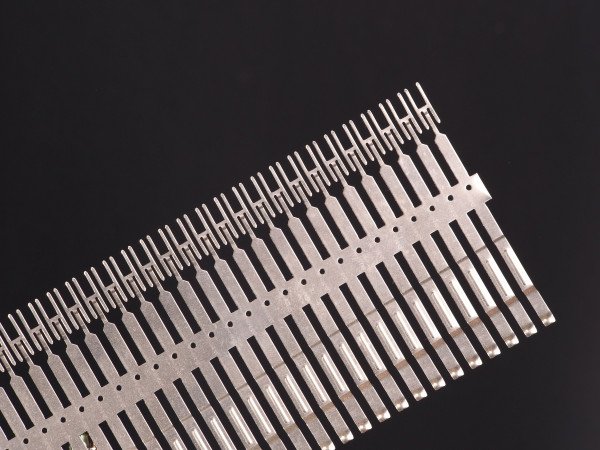

- Leadframes

- Electronic parts

Your contact person