ENIG process

ENIG process

Electroless nickel - immersion gold

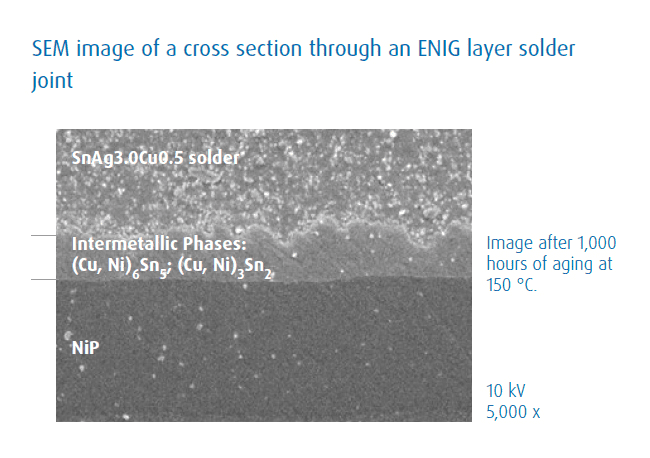

Electroless nickel – immersion gold (ENIG) is a flat, solderable, metallic finish on printed circuit boards and ceramic substrates. It serves to protect the copper from oxidation and ensures solderability and bondability with aluminium wire.

In this process, the surfaces and vias intended for the finish first have a nickel layer applied to the copper in an electroless process as a diffusion barrier and, in a second step, a thin gold finish is applied. The gold reliably acts to prevent nickel oxidation and significantly determines the very good solderability of the ENIG surface, even after printed circuit boards have been stored for extended periods.

A pretreatment that is outstandingly attuned also allows fine line circuitries to be coated reliably. Of course, the ENIG surface also fulfils current RoHS and WEEE requirements.

Advantages

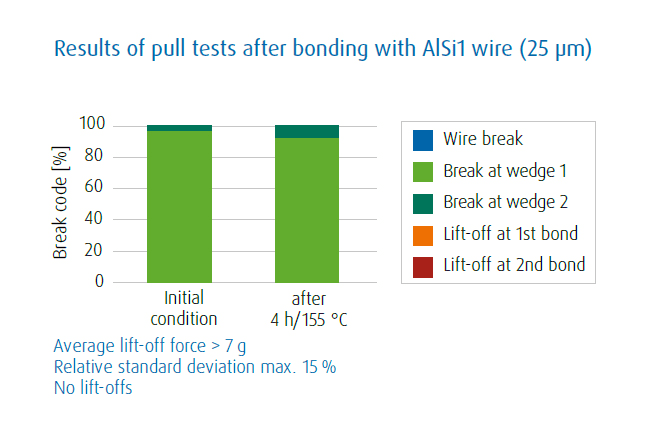

- Surface finish for printed circuit boards for soldering and bonding with Al-wire

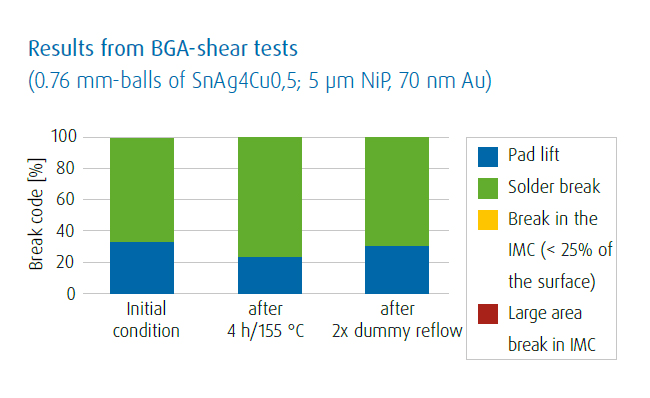

- High solder joint reliability with lead-free and lead-containing solders

- Outstanding contact surface

- Electroless nickel deposition with best edge covering and fine line capability

- More cost-effective than electrolytic gold layers

Applications

- Printed circuit boards and substrates in SMD-, CoB- and HDI-technology

- PCB for soldering and Al-wire bonding applications

- Contact surfaces for keypads

Your contact person