DIG process

DIG process

Plating of direct immersion gold

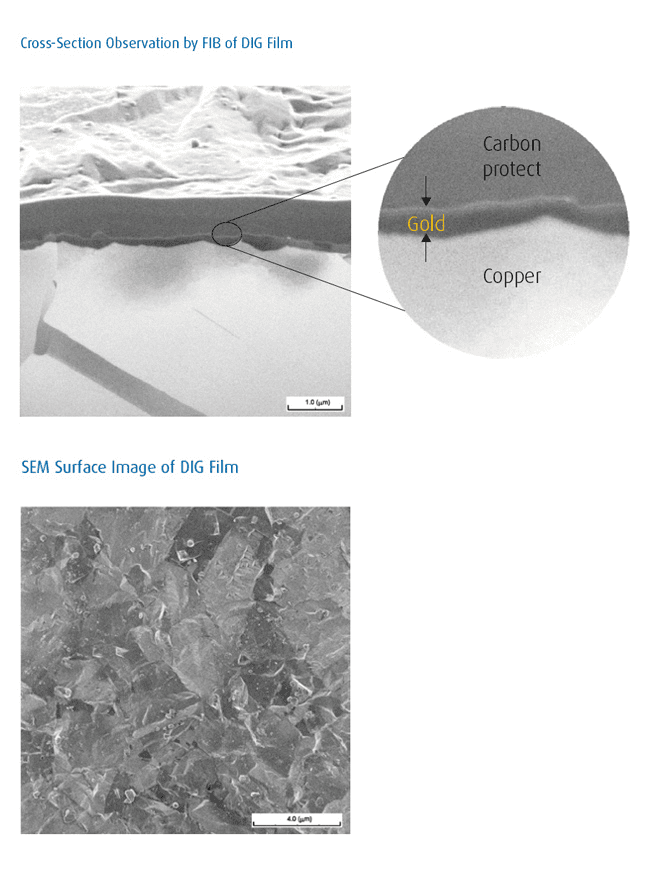

Ever increasing electric components density and high frequencies of signal transmission require new concepts of final finishes in PCB manufacturing, too. By direct gold plating on copper (DIG) beside ISIG and EPIG a further process has been provided, which is free from nickel and has a high HF performance.

Due to its outstanding film characteristics DIG deposits are very well suited to withstand the higher requirements of PCB designers concerning fine pattern ability and high performance regarding soldering and wire bonding.

Advantages

- Nickel free coating

- Deposits with high HF performance

- Suitable for (ultra) fine pitch layouts

- Ductile film compatible for flex PCB applications

- Dense and homogenous gold protection layer up to 0.3 μm feasible

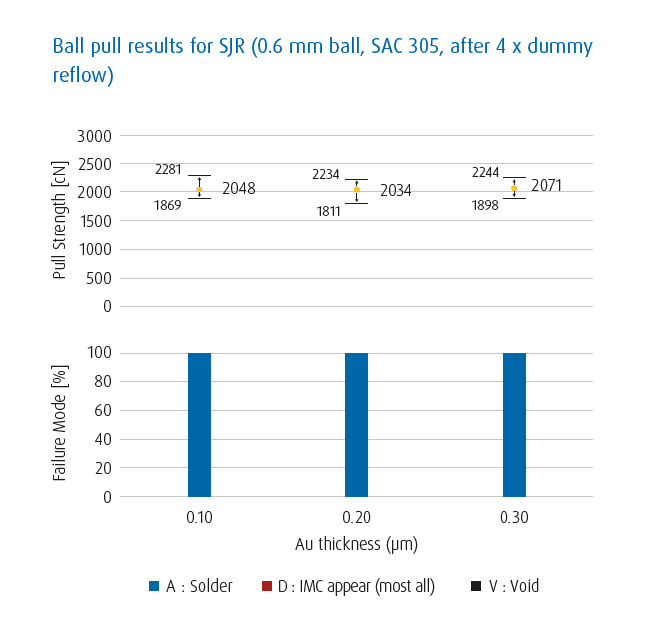

- High solderjoint reliability (SJR) due to low void formation

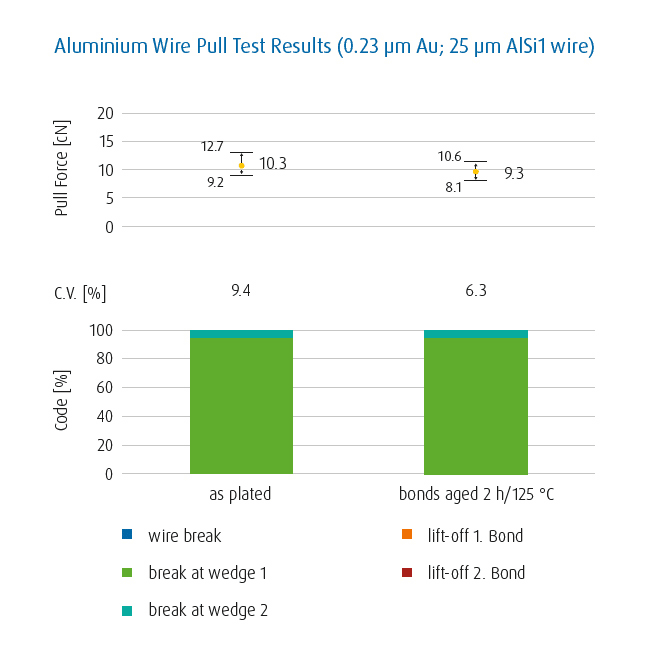

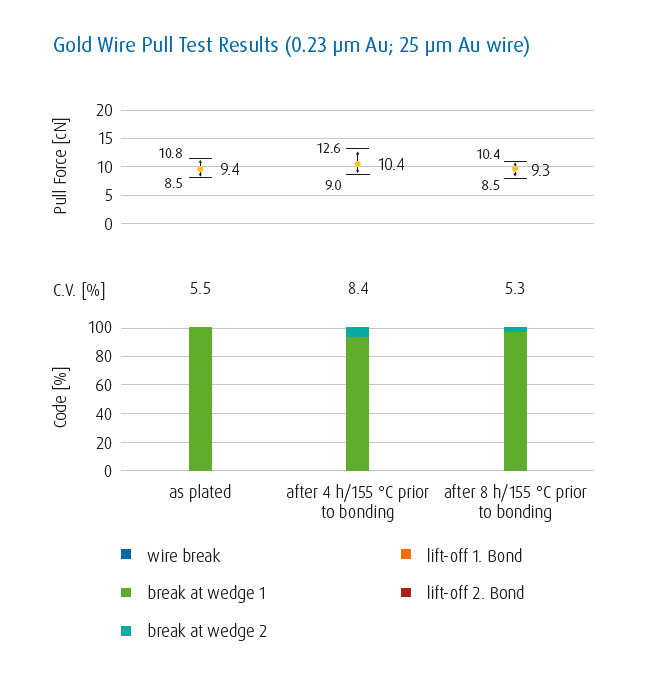

- Excellent Al-, Au-, Cu-(Pd coated) and Ag-wire bondability

- Low plating cost due to few process steps

Applications

- Flexboard PCB (FPC)

- Multi-functional assembly

- Fine pattern PCB design

Your contact person