Pioneering platinum coating of Porous Transport Layers (PTL) and Bipolar Plates (BPL) made of titanium

Especially against the backdrop of the energy transition and the increasing demand for sustainable and clean energy sources, hydrogen is seen as a promising energy carrier of the future.

In view of current technological developments and the urgency of reducing CO2 emissions, water electrolysis currently appears to be the most feasible and advantageous process for producing hydrogen. Not only does it enable CO2-neutral production when powered by renewable energy, but it also offers the flexibility to be implemented at various scales - from small decentralized units to large industrial plants.

Electrolyzers as key components

Electrolyzers are key components in water electrolysis, a process in which water (H2O) is split into its components hydrogen (H2) and oxygen (O2) with the help of an electric current.

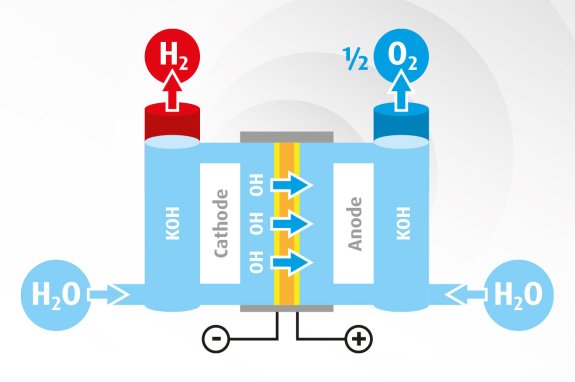

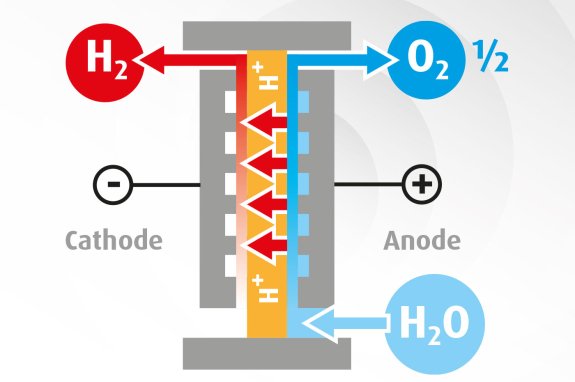

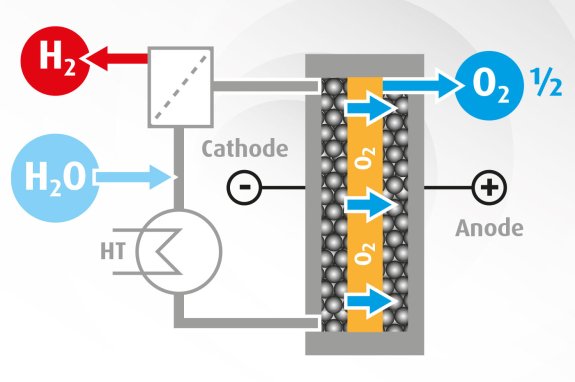

Common technologies are:

This technology is technically mature and has been used industrially for decades. It works with an aqueous solution of potassium hydroxide (KOH) as the electrolyte and uses relatively inexpensive materials.

PEM electrolyzers are compact and can react quickly to load fluctuations, which makes them attractive for integration into renewable energy systems. However, they require more expensive materials such as precious metals.

This technology is particularly efficient as it can use waste heat to reduce the energy required for electrolysis. However, it is still at an early stage of market development.

At present, PEM electrolysis appears to be the most suitable technology for a broad market launch. It offers high efficiency even at large scale, fast response times and the ability to operate at high pressures, which can reduce the cost of hydrogen storage and distribution. Although the material costs are higher than for AEL, the advantages in system integration and operational flexibility could offset these disadvantages, especially when it comes to utilizing fluctuating energy sources such as wind and solar power.

A PEM (Proton Exchange Membrane) electrolyzer is a complex system that uses a membrane electrode assembly (MEA) to split water into hydrogen and oxygen. The structure of a PEM electrolyzer comprises several key components:

The heart of the electrolyser is the MEA, which consists of a proton-conducting polymer membrane flanked on both sides by catalyst electrode arrays. This membrane enables proton transport and at the same time separates the gases to prevent mixing.

PTL are responsible for the distribution of water on the catalyst surface and the removal of gases from the reaction zone. They must have a high porosity to allow the gas flow and at the same time have good electrical conductivity to act as part of the circuit.

These plates serve as electrical conductors between the cells and as carriers for the gas distribution structures. They must be corrosion-resistant as they come into contact with both the hydrogen and oxygen produced.

Titanium as the undisputed base material

BPL and PTL made of titanium have proven to be extremely durable in the oxygen-rich environments of PEM electrolyzers. This and other advantages make titanium the preferred material for future PEM designs compared to stainless steel:

- Titanium ensures a long service life due to good oxidation and corrosion resistance

- Titanium is particularly suitable for low pH values

- Titanium helps to reduce the overall weight due to its low density

- Titanium has high mechanical stability even with large pressure fluctuations

Platinum coatings significantly improve performance

Even a thin layer of platinum on BPL and PTL made of titanium significantly improves the performance and service life of the electrolyzer:

- Platinum offers superior electrical potential for PTL

- Platinum acts as a catalyst and increases the efficiency of electrochemical reactions

- Platinum reduces ohmic resistance and improves overall performance

- Platinum improves corrosion and oxidation resistance

Platinum protects against degradation

Umicore is proud to have the know-how to deposit platinum on titanium components for PEM electrolyzers in a way that is safe for humans and the environment. Our established platinum electrolytes, already proven in numerous technical applications, form a solid basis for this specially developed process, which does not require corrosive or toxic chemicals.

Safe platinum coating for the requirements of modern PEM electrolyzers

We are able to deposit very thin platinum layers on titanium components, which achieve the best possible electron conductivity and therefore outstanding efficiency due to their uniformity and matrix state. In addition, we are able to guarantee the optimum layer thickness distribution for the respective system and thus keep the costs for the use of platinum low. This enables us to offer our customers high-quality yet economically attractive solutions.

We see coating as our core competence and take this work step off our customers' hands.

Sebastien Fourgeot

(Project Manager Electrolyzers)

Umicore has set up electroplating centers worldwide in order to be able to coat a wide variety of components in a customer-oriented and sustainable manner. These centers are at least partially automated and scalable at any time, so that even large order quantities can be processed in a short time. This guarantees flexible and efficient production that meets the needs of our customers.

In addition to the electrochemical deposition of platinum, we offer two alternative processes: Firstly, High Temperature Electrolysis (HTE) in a globally unique molten salt process, which has already proven successful for coating electrodes. The second is Physical Vapor Deposition (PVD), which is primarily used in the production of semiconductors. Both processes enable us to apply platinum to titanium in extremely thin and precise layers.

Our decades of experience in the application of these processes make Umicore the most competent partner for the platinum coating of components for PEM electrolyzers. You can rely on our know-how and innovative strength to successfully implement your projects.

The probably most efficient and environmentally friendly coating system for your PEM electrolyzer

Let us explore together what options we can offer you. As an experienced coating specialist, a subsequent test coating of your components is a matter of course - so together we can quickly find the most efficient coating system for you.

Please note that our commitment to you does not end with the successful implementation of our solution. We are also there for you after commissioning and support you whenever you need us - worldwide.

Markus Legeler

Manager Sales International

markus.legeler@eu.umicore.com

Start Teams Chat

+49 7171 607 204 (Office)

+49 170 9370 163 (Mobile)

LinkedIn | Xing

Website content matching this page