Ruthenium as a sustainable substitute for palladium plating with significant price advantages

![]()

For years, palladium has been considered the ideal intermediate or final layer among platinum metals. Now the balance of power is changing – our ruthenium plating process RUTHUNA® beats palladium, which has been the preferred choice up to now, in all relevant properties.

Click here for the Chinese version.

(Redirect to the Chinese website of the Umicore Group)

The king is dead, long live the king

The well-known phrase with which the death of the old king was announced in France and the new one proclaimed at the same time now also applies to electroplating. Even if palladium still exists, especially in the decorative sector, there is little to be said for its continued use, because of our RUTHUNA® product family, which has been greatly expanded in the meantime. Especially as replacing the electrolytes in the production landscape is possible with almost no effort due to its pH neutrality.

RUTHUNA® gives you a competitive advantage on all levels

Of course you, but also your customers, look at the price. The costs for energy, buildings, raw materials, etc. are rising – in order to be able to continue to produce economically and sell at a competitive price, savings are necessary here.

Nevertheless, and especially nowadays, price advantages are no longer the only decisive factor. For example, your customers, your suppliers and therefore also you as a producer are concerned with the issue of sustainability. Where do your raw materials come from, how are they processed and what happens to the "waste products" – your environment demands sustainable action from you as a producer.

At the same time, quality is a key factor. Not only shape and colour, but also quality features such as a long service life of your products automatically pay into your image account – the basis for customer loyalty and new customer acquisition in a highly competitive market.

In all these points and more, ruthenium plating with RUTHUNA® alone cannot, of course, lead to the goal - but it can play its part. With RUTHUNA® you gain a clear competitive advantage.

Over 70 % price advantage*

Reliable source of raw materials

Reliable source of raw materials

Highest possible abrasion resistance

Highest possible abrasion resistance

Depositable on non-ferrous metals

Depositable on non-ferrous metals

Reuse of ruthenium

Reuse of ruthenium

Our RUTHUNA® product family has been specially developed for the decorative sector. Our ruthenium electrolytes offer extraordinarily innovative plating systems, which provide an optimal solution for every challenge in the segment – and are thus the new standard for the decorative industry.

Our ruthenium plating (as a substitute for palladium) not only has price advantages

Palladium owes its predominance primarily to its price advantage within the platinum group of metals at the time. Compromises with other properties were willingly accepted because of this. RUTHUNA® electrolytes, on the other hand, not only impress with their cost-effectiveness – they are also advantageous in terms of sustainability, quality, user-friendliness and, in the technical field, for selected applications in the area of functionality.

Over 70 % price advantage*

The palladium price has continued to develop over the past few years and has in the meantime also exceeded the €100/g mark. In contrast, the ruthenium price has been stable for years and is much lower. In addition to the price advantage, it is precisely this stability that makes it possible to calculate with foresight.

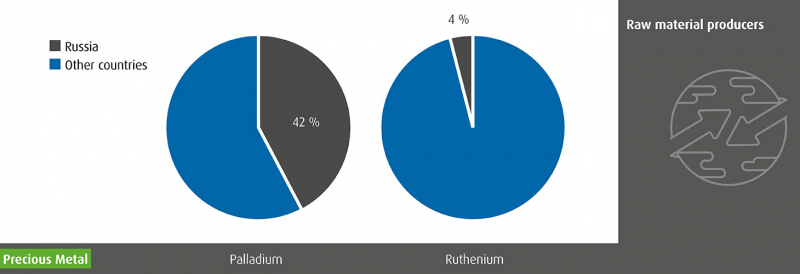

Reliable source of raw materials

Russia has not proven to be a reliable partner due to the events in the conflict with Ukraine. However, Russia is the largest palladium producer with 90 tons per year. In contrast, 87 % of ruthenium comes from South Africa and only 4 % from Russia (as of 2020).

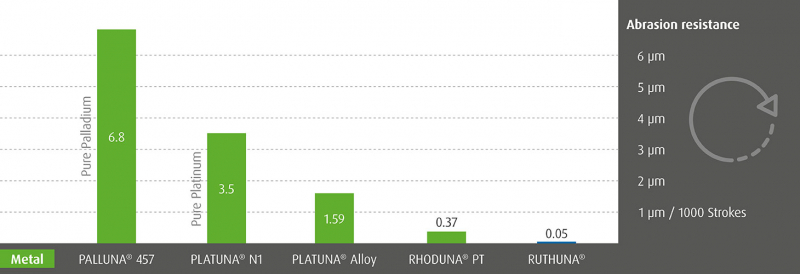

Highest possible abrasion resistance

The abrasion resistance of platinum metals is usually achieved with the addition of ruthenium. However, pure ruthenium is by far the most abrasion-resistant platinum metal – our specially manufactured RUTHUNA® therefore also convinces in the Bosch-Weinmann test (plating layer removal per 1000 rubbing processes with a sandpaper).

Depositable on non-ferrous metals

With RUTHUNA® we have made sure that the electrolyte has a neutral pH value. This allows you to plating directly onto non-ferrous metals such as copper, nickel or white bronze. Regardless of the plating surface, our RUTHUNA® can thus replace your previously used palladium 1:1 without any effort.

Reuse of ruthenium

We are concerned to act sustainably in everything we do and to support our customers in this respect. So we close the circle – and you benefit again in economic terms when we take back the ruthenium you have processed from used electrolytes and charge it at the current daily rates.

![]()

Our ruthenium process is perfect for final layers - but also shows its advantages when plating as an intermediate layer

Of course, RUTHUNA® can be used directly as a finishing layer. We offer RUTHUNA® in different versions, which mainly differ in composition and thus in colour shade. Light coatings with an L* value (L*a*b* colour space) of 74 to very dark coatings with an L* value of 63 are possible as standard.

However, ruthenium is not always desired as a final plating layer or the brightness is not light or brilliant enough. Here, RUTHUNA® has the natural limitation in colouring – palladium (L* value: 84) or rhodium (L* value: 90) have their preference here. Nevertheless, you can take advantage of the obvious benefits of RUTHUNA® by using it as an intermediate layer without any problems.

RUTHUNA® as final layer

By replacing palladium with RUTHUNA® you save over 70% in precious metal costs. At the same time, the high-quality final layer, which also protects against corrosion, shines with practically lifelong abrasion resistance.

RUTHUNA® as intermediate layer

As an intermediate layer, RUTHUNA® is also significantly more economical. Even with an intermediate step that must be taken with a gold final layer to avoid the formation of corrosion when gold comes into direct contact with ruthenium.

If the corresponding end layer is partially rubbed through, this is not visible to the naked eye due to the color-matched intermediate layer.

![]()

The technical applicability of RUTHUNA®

Our RUTHUNA® was primarily developed and optimised for decorative use. Nevertheless, it is of course possible and also makes sense for various technical applications to think about changing the previous precious metal. In addition to the economic and sustainable aspect, functional properties such as the reduced sparking in current-conducting applications also make a change worthwhile. Only the plating process still limits the applicability in all technical areas.

For example, RUTHUNA® is recommended for the following technical applications:

- Reed switches

- Inkjet printer foils

- Surfaces of catalytic converters

- Electrolysis electrodes

![]()

Presentation with further details on tuthenium plating with RUTHUNA®

In a 10-minute presentation, our expert Joachim Grimm explains in detail in the video which advantages the RUTHUNA® product family offers:

Agenda

1) Sourcing and supply

2) Background of pricing the PGM's and -alloys

3) Kinds of electrolytes available

4) Examples and layer sequences

5) Layer characteristic

6) Approaches and hints of application

![]()

Finely tuned RUTHUNA® products – the right electrolyte for every application

Not every challenge is the same, not every production environment is identical, and our customers' goals also vary. So one product cannot be the universal solution for your specific task.

The RUTHUNA® product family currently consists of four products. Each with individual characteristics to achieve exactly your goal. You can find a comparative overview of our unique product range here:

* Precious metal price advantage compared to palladium plating (as of September 2022).

![]()

Markus Legeler

Manager Sales International

markus.legeler@eu.umicore.com

Teams Chat starten

+49 7171 607 204 (Office)

Website content matching this page