RHODUNA® Alloy – abrasion resistant like no other bright white rhodium coating

Umicore's RHODUNA® Alloy has earned the title "the bright queen" due to its superiority over other rhodium coatings on the market. In addition to its brilliant white final layer, it not only has all the benefits of pure rhodium layers - it also 'shines' with a clear cost advantage and unsurpassed abrasion resistance. It is precisely this abrasion resistance that has now been impressively confirmed by the independent professional committee for economic development FRANCÉCLAT in Paris (France), which serves the jewelry industry, among others.

Click here for the Chinese version.

(Redirect to the Chinese website of the Umicore Group)

Still the bright queen among rhodium electrolytes

RHODUNA® Alloy is branded “the bright queen” of rhodium & rhodium alloy deposits due to its best in class performance for appearance quality and abrasion resistance. It's no wonder it's the first choice of leading manufacturers worldwide and has become an indispensable part of many finishing portfolios for decorative and technical applications.

![]()

RHODUNA® Alloy is here to stay

RHODUNA® Alloy was introduced in 2010 as the first available rhodium-ruthenium electrodeposit in the industry. And still, years after its development, the performance is unsurpassed. Results from independent testing agree with satisfied customers - RHODUNA® Alloy provides exceptional abrasion resistance compared to pure rhodium finishes.

![]()

There is no reason for any other rhodium coating

The use of pure rhodium makes neither economic nor qualitative sense, so there is no reason to use pure rhodium as a final layer. When evaluating pure rhodium for your application, consider choosing better performance at a lower cost. RHODUNA® Alloy has all the positive characteristics of pure rhodium layers with the added benefit of excellent throwing power and uniform layer thicknesses, even in complex components.

Much better abrasion resistance

Much better abrasion resistance

More uniform layer thickness

More uniform layer thickness

Brilliant white like pure rhodium

Equally corrosion resistant

Equally corrosion resistant

About 22 % cost advantage

The goal in developing our rhodium-ruthenium electrolyte (consisting of 75% rhodium and 25% ruthenium) was to achieve maximum cost savings without compromising on quality.

Our RHODUNA® Alloy is more than an alternative

The original goal of creating a cost-effective alternative to pure rhodium has been exceeded. RHODUNA® Alloy has become the better rhodium.

Much better abrasion resistance

The independent test report by FRANCÉCLAT proves that the electrolyte RHODUNA® Alloy has a significantly better abrasion resistance than pure rhodium. In a Turbula abrasion test, the colour values were compared after 2, 5 and 10 hours. The layer underneath the final layer is protected best with RHODUNA® Alloy, which is visually confirmed by the constantly high L* values.

More uniform layer thickness

In direct comparison, our RHODUNA® alloy shows a significantly better throwing behaviour. This is particularly evident in complex shaped jewelry - for example, with recesses for the inlay of gemstones. For rhodium electrolytes, deposition in such jewelry is usually difficult, which can make the gemstones appear dull and pale.

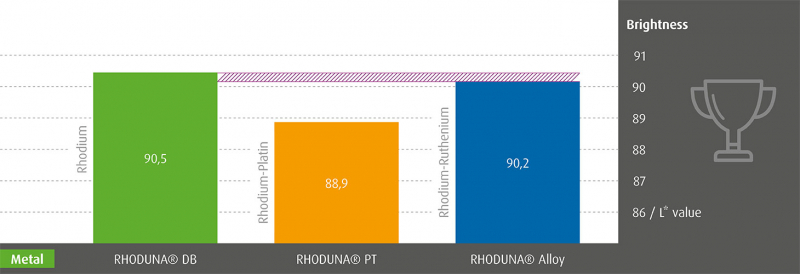

Brilliant white like pure rhodium

Through specific electrolyte development, we have succeeded in developing a coating whose whiteness is almost equal to that of a pure rhodium coating. Thus, the L-value (whiteness) of the RHODUNA® Alloy coatings in the FRANCÉCLAT test report is only 0.3 points below that of pure rhodium electrolyte coatings and is thus not visible to the naked eye.

Equally corrosion resistant

Like rhodium coatings, rhodium-ruthenium alloy deposit thicknesses are between 0.05 μm and 0.2 μm. When evaluating corrosion behavior, no differences can be discerned between the deposited layers, as evident by the sulfide and welding resistance in FRANCÉCLAT's independent tests.

Significant cost advantage

Ruthenium has been significantly cheaper than rhodium for many years due to availability and demand, which gives our rhodium-ruthenium alloy a decisive price advantage. Compared to conventional rhodium electrolytes, RHODUNA® Alloy offers a cost saving of about 22 percent.

RHODUNA® Alloy is also attractive for technical applications

Ease of use, appealing design and high performance have long been the main arguments for buying wearables and mobile phones. Increasingly, however, subtle differences such as durability and compatibility with fast chargers are becoming crucial.

RHODUNA® Alloy meets the new requirements for wearables and mobile phones

Commonly used gold-plated charging contacts & connectors (USB-C, Pogo Pin, etc.) have well-known performance limitations. Gold-plated contacts corrode during the charging process if they have previously come into contact with salt water, swimming pool water, sweat or drinks, which leads to numerous complaints and the expensive replacement of damaged devices.

Specify electrical contacts with RHODUNA® Alloy and protect against corrosion to ensure the fast charging capability of electronic devices.

Interview with further details on RHODUNA®

The advantages and application areas of RHODUNA® for coating technical and decorative surfaces are summarised again in the following video. Martin Stegmaier (Division Manager Decorative Applications) and Joachim Grimm (Sales and Technical Service) answer the most important questions in a compact interview in a simple and understandable way. A special focus is on the subsequently created RHODUNA® Alloy Black, which can bring very dark surfaces to your applications.

Agenda

1) Introduction

2) Advantage of RHODUNA® alloys

3) Expansion with a dark version of RHODUNA® Alloy

4) Features of RHODUNA® Alloy Black

5) Application fields of RHODUNA® Alloy Black

6) Feedback on RHODUNA® Alloy Black

7) Outlook

A selection of high quality as well as economical rhodium coatings

RHODUNA® Alloy is our brilliant bright queen, but not your only alternative to pure rhodium coating. Depending on the composition, RHODUNA® PT offers you another considerable price-saving potential. RHODUNA® Alloy Black, on the other hand, gives your application an incomparably noble dark rhodium surface.

|

Lightness |

Layer Density [g/cm³] |

PM price (calculated) | Metal (in Prozent) |

Layer price (1 µm / 1 dm² ) |

Cost saving (compared to Rh) |

|

| Rhodium (pure) | 90,5 | 12,41 | 325.70 € | 100 (Rh) | 40.42 € | 0 % |

| Our alternatives | ||||||

| RHODUNA®-Alloy 1 | 90,2 | 12,42 | -- | 75 (Rh) : 25 (Ru) | 31.65 € | 22 % |

| RHODUNA® PT (50:50) | 88,9 | 15,72 | -- | 50 (Rh) : 50 (Pt) | 30.38 € | 25 % |

| RHODUNA® PT (20:80) | 88 | 18,72 | -- | 20 (Rh) : 80 (Pt) | 21.38 € | 47 % |

| RHODUNA®-Alloy Black 1 | 55-66 | 12,43 | -- | 50 (Rh) : 50 (Ru) | 22.91 € | 43 % |

Advice and technical service right from the start

Our RHODUNA® product family sounds interesting to you? Then let's talk about it. We offer you comprehensive consultation in advance to clarify all relevant details. On this basis, you should be able to make a well-founded decision for or against our processes.

Of course, we are also available to you at any time after the successful integration of the products - on site worldwide if you wish.

Markus Legeler

Manager Sales International

markus.legeler@eu.umicore.com

Teams Chat starten

+49 7171 607 204 (Büro)

Website content matching this page