Precise application of hard gold saves material costs: AURUNA® 526 & 527

Whether applying paint to a protected wooden facade or pouring concrete for a stable foundation, even distribution is crucial for quality and function. This is usually not a problem in easily accessible areas or with simple shapes. However, as soon as the geometry becomes more complex, for example due to cavities, depth levels, or shape deviations, irregularities in layer thickness can quickly occur. These lead to weak points in areas with insufficient material and unnecessary consumption in areas with excessive material application.

This also applies to electrolytic plating: only when the layer is applied evenly and in sufficient thickness can technical requirements be reliably met while optimizing costs.

An even layer thickness distribution of gold improves competitiveness

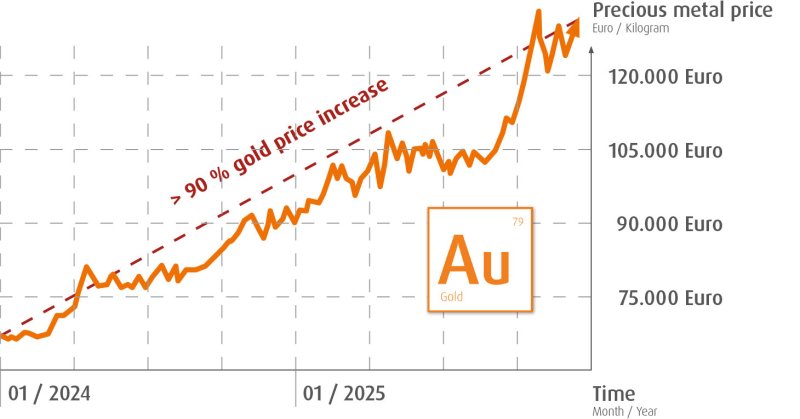

In practice, however, overcoating often occurs in order to avoid quality losses due to partially insufficiently plated areas. This inevitably results in a monetary competitive disadvantage – especially now that the price of gold is at a record high.

The price of gold has nearly doubled in the past two years. This makes the cost of precious metals even more significant.

Good layer thickness distribution pays off more than ever. Less overcoating means lower precious metal costs. However, electrochemical and physical laws make it difficult to achieve uniform, high-quality, and thus cost-optimized deposition.

Challenge: complex parts

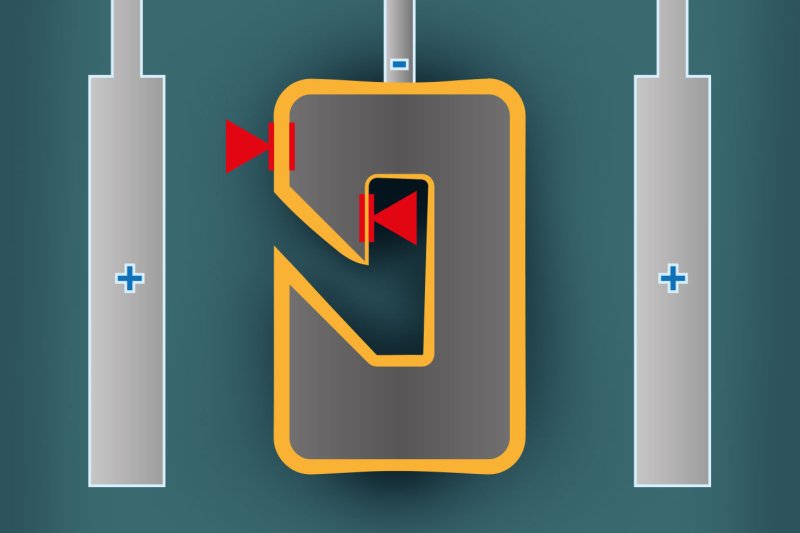

In electrolytic plating, the more uniform the coating thickness, the less precious metal is required. Conventional hard gold electrolytes tend to deposit more gold in areas close to the anode, while less is deposited in areas that are difficult to access, such as the inside of hollow bodies, as in plug contacts or contact sockets. This often means that an unnecessary amount of gold must be used at other component locations in order to achieve the required minimum layer thickness at specified measuring points.

Challenge: Bulk material coating

Plug contacts or contact sockets are often bulk materials and, for reasons of efficiency, are ideally plate with hard gold in a small parts mass coating process. The barrel and vibration electroplating systems predestined for this purpose allow a large number of parts to be plated, but with varying current density conditions for each individual part during the plating process – achieving an optimally distributed gold layer in the desired thickness often causes difficulties here.

With the hard gold electrolytes AURUNA® 526 and AURUNA® 527, we have been offering solutions for over 20 years that enable uniform layer thickness distribution even with complex geometries of bulk material parts thanks to excellent depth dispersion. This allows us to combine quality with cost-effectiveness.

The plated components can also be used in demanding areas such as defense technology, as their purity and hardness, reliable functionality, and durability enable them to meet the strict ASTM standard.

ASTM Standard B 488-01 Typ I, Code C

The high-quality coating characteristics of both processes mean that there is no need to compromise on technical properties such as contact resistance or abrasion resistance. Combined with very even coating distribution, even in geometrically complex applications, they are therefore particularly suitable for technical components such as pin, spring, and plug contacts, as well as contact sockets and sleeves.

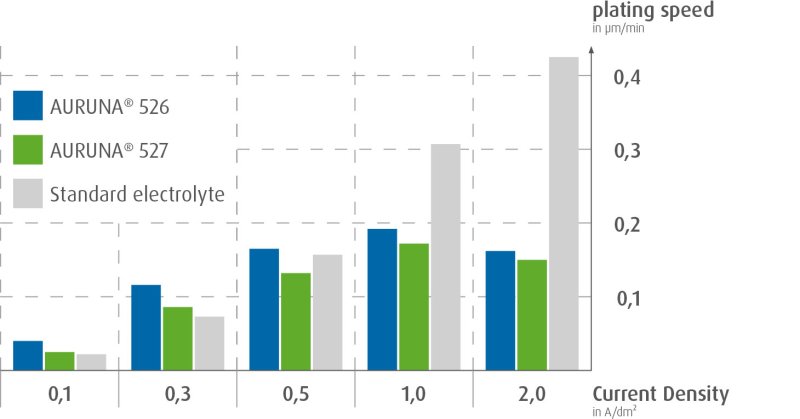

Layer distribution

Compared to a standard electrolyte, both AURUNA® electrolytes exhibit a higher deposition rate at low current densities and a significantly lower response to high current densities, or rather, a plateau in the deposition rate at high current densities. This results in more uniform layers in the application area of bulk material barrel/vibration coatings – overcoating and the so-called dog bone effect are significantly reduced.

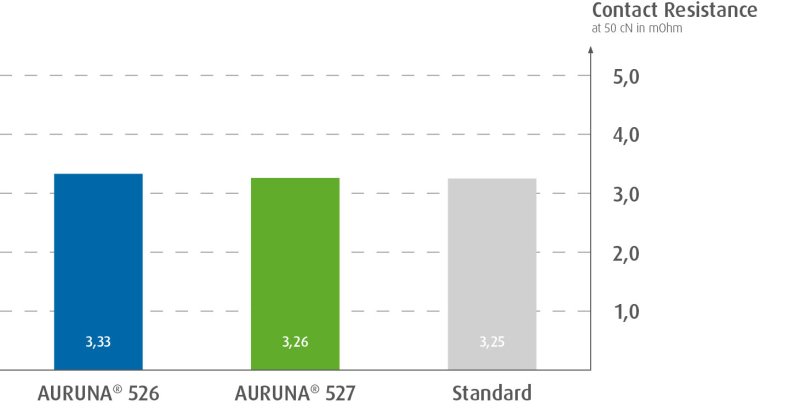

Contact transition resistance

A comparison of standard electrolytes in hard gold plating has shown that the deposited layers of both AURUNA® electrolytes meet the highest technical requirements. For example, both have an almost identical, low contact transition resistance. There are also no measurable differences in other significant characteristics such as abrasion resistance.

Product pages

Both electrolytes have a wide operating window, stable long-term behavior, and the possibility of electrolyte replenishment without new make-up by adding electrolyte – even in continuous operation. Information on further electrolyte and layer characteristics can be found on the respective product pages.

AURUNA® electrolytes offer you a cost advantage when gold prices are high

In times of high precious metal prices, the optimal depth dispersion of AURUNA® electrolytes really comes into its own, turning an economic advantage due to lower material costs into a decisive competitive advantage, as you do not have to compromise on quality and function.

Rely on high-performance solutions for your hard gold plating. Our team will be happy to advise you on the possible applications and support you in integrating the right AURUNA® electrolyte into your process landscape.

Markus Legeler

Manager Sales International

markus.legeler@eu.umicore.com

Start Teams Chat

+49 7171 607 204 (Office)

Website content matching this page