New connector plating standard for plug contacts in high power applications

![]()

Many requirements for the establishment and expansion of an efficient charging infrastructure have been or are currently being created: an increasing number of charging stations, expanded battery capacities or rising charging power. However, a sustainable solution for longevity high-current plugs is still lacking. Current systems for transferring high charging power from the power source to the battery are still far from satisfactory for manufacturers and suppliers.

Click here for the Chinese version.

(Redirect to the Chinese website of the Umicore Group)

The technical requirements for the plating of high power connectors have not been met so far

Silver is the element in the periodic table with the highest electrical conductivity and thus the prerequisite for connector contacts with the greatest possible power transmission. However, both fine silver (pure silver) and hard silver coatings (silver alloys) still do not meet all the technical properties required by the industry in terms of quality (see adjacent list).

The desire for significant longer durability of high-performance silver coatings for such high-power applications (e.g. high current plugs) is obvious - no wonder, this is the basic prerequisite for longevity and thus improved cost-effectiveness.

![]()

Longevity means competitiveness

The problem is particularly evident in the example of electric cars. Here, the vehicle inlet is permanently installed and a shortened life cycle often means an early, costly and potentially image-damaging replacement of the component.

Increased costs can also arise on the charging infrastructure side due to limited durability of the plug components on the charging station. The charging plugs are plugged in many times in daily use and can show wear of the silver surfaces within a short time. However, since end customers expect reliable charging with the shortest possible charging times, the entire charging pistol must be replaced in the event of wear and thus limited charging function. Besides the additional costs for materials, time and service, this can also result in sales losses due to reduced usage or the downtime of the column.

High electrical and thermal conductivity

Temperature-stable hardness up to the end-of-life

Temperature-stable hardness up to the end-of-life

Extended lifetime (longevity) of the contacts/connectors

Extended lifetime (longevity) of the contacts/connectors

Improved wear resistance and corrosion resistance

Improved wear resistance and corrosion resistance

High number of mating cycles without performance degradation

High number of mating cycles without performance degradation

Our silver-graphite dispersion electrolyte ARGUNA® C-100 is specially developed for connector contacts used in high-power applications (e.g. high-power charging / HPC). A stable layer system with maximum charging performance without restrictions over the entire lifetime of the charging connectors is the result - and thus the new standard for the industry.

ARGUNA® C-100 is based on a simple function

Graphite particles perfectly embedded in the silver layer achieve extraordinary abrasion resistance and thus the high reliability and durability of the plug contact required by the industry. This is made possible by a optimized graphite component which, embedded in the silver matrix, serves as a solid lubricant. In this way, abrasion on the entire contact zone during the mating process can be reduced to a negligible level.

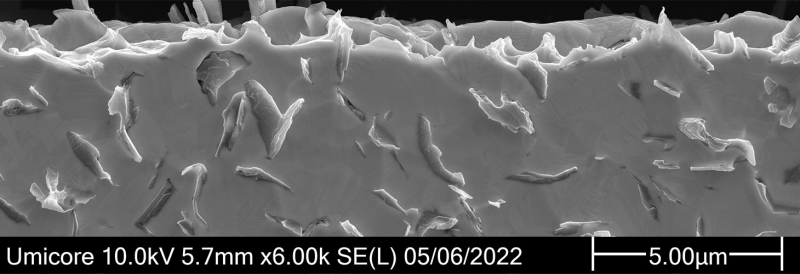

Graphite embedded in perfection

The statistically random distribution and incorporation of the graphite lamellae in the electrodeposited silver matrix is shown by a prepared ARGUNA® C-100 layer under a scanning electron microscope. Here, the silver matrix was selectively etched back and the incorporated graphite lamellae remain in their position.

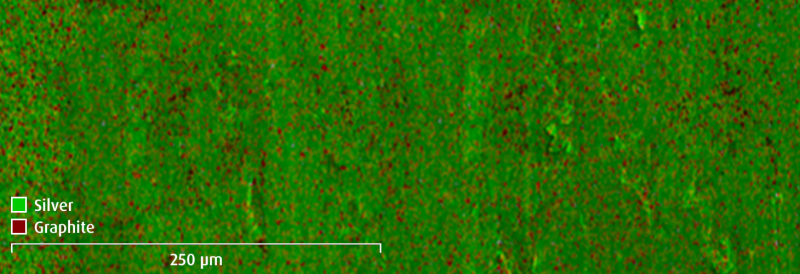

A view by element scan (EDX X-ray spectroscopy) of the contact surface shows the uniform and excellent distribution of the graphite over the surface.

A new surface is created with each friction process and the abraded tips of the graphite lamellae are distributed over the friction surface. The usual abrasion of the silver surface is prevented, the contact resistances are kept small and thus a continuously high charging performance is ensured.

Exceptional longevity in high current plugs with maximum load performance

Fine silver is the benchmark in terms of electrical and thermal conductivity. However, the tendency to cold welding in combination with a low hardness causes a high coefficient of friction and leads to wear of the silver layers when mated frequently.

Hard silver has a higher hardness and shows significantly improved vibration resistance. However, added metals have a negative effect on electrical conductivity and the coefficient of friction is sometimes close to the fine silver level.

ARGUNA® C-100 combines and extends the positive properties of fine and hard silver. On the one hand, the fine silver matrix has excellent electrical conductivity. On the other hand, the solid lubrication of the graphite simultaneously increases abrasion resistance and thus reduces wear even with a high number of mating cycles.

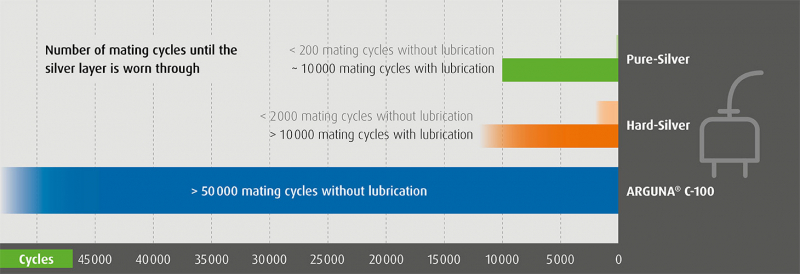

Over 50,000 mating cycles*

An end-of-life tribometer test shows the low and stable coefficient of friction of the ARGUNA® C-100 coating system. Even after more than 50,000 mating cycles, an intact silver graphite layer can be detected - and cross-compatibility with other mating contact materials (e.g. fine, hard or dispersion silver layers) completes the extended functionality in the field.

Maximum performance

Fine silver has the highest electrical and thermal conductivity of all metals and is therefore the functionally preferred charging contact coating to date. ARGUNA® C-100 lasts many times longer in comparison and tends to show lower contact resistance.

Plating for economical and functional high power connectors

The ARGUNA® C-100 layering system is designed for high-power charging with increasing charging powers of 500 kW and more. The robust layering properties maximize performance and longevity:

- Consistent coating performance at elevated temperatures (>150°C)

even with local temperature rise in the contact point - Stable layering properties under humidity and dust

and other exposed environmental conditions - Maintenance-free layer system over the entire service life

the otherwise necessary lubrication is not required - Cross-compatibility with existing infrastructure

matching the existing connector types in the field

ARGUNA® C-100 thus offers a contact layer on your connectors that is clearly superior to conventional coatings: more than 50,000 mating cycles* without adverse wear and therefore the best possible charging performance at all times without restriction - the new standard in this field.

Webinar with further details on ARGUNA® C-100

In a 20-minute webinar and the subsequent Q&A session, Robert Ziebart (Sales & Technical Customer Support) shows in great detail the advantages of our silver-graphite dispersion electrolyte ARGUNA® C-100.

Webinar in English language

Meeting New Requirements for High Voltage EV Charging Connectors

Agenda

1) Introduction to Umicore (2:45)

2) EV Charging Trends (4:40)

3) Performance requirements for charging connectors (8:18)

4) Challenges of existing electroplating technology (9:40)

5) Silver graphite electrolyte for increased reliability (11:18)

6) Wear performance testing (14:27)

7) Summary (18:51)

8) Q&A (21:05)

* 50,000 mating cycles are the result of end-of-life tribometer tests under laboratory conditions

Markus Legeler

Manager Sales International

markus.legeler@eu.umicore.com

Teams Chat starten

+49 7171 607 204 (Office)

Website content matching this page