New benchmark for platinum coating of technical applications

![]()

Electroplating technology has a new benchmark for coating with pure platinum: PLATUNA® PT. The electrolyte enables the deposition of exceptionally thick and at the same time very homogeneous and absolutely crack-free platinum layers.

Coatings with PLATUNA® PT are convincing in almost all technical applications. Whether as a visually appealing, high-gloss top layer or as a functional intermediate and final layer.

Click here for the Chinese version.

(Redirect to the Chinese website of the Umicore Group)

Perfect platinum layers for high-quality applications

We have added three new electrolytes to our PLATUNA® product family. While PLATUNA®-Alloy RH as a high-quality platinum alloy and PLATUNA®-Alloy RU as a cost-optimised platinum alloy were developed primarily for decorative applications, PLATUNA® PT has been designed for technical requirements from the outset.

The PLATUNA® PT electro deposited layer consists of 99.9 % pure platinum and has the following properties:

|

Crack-free layers up to 5 µm |

|

Very uniform thickness distribution with a density of 21.4 g/cm³ |

|

Hardness of approx. 350 HV |

|

Absolutely fog-free, without colour cast, very bright (L* value:87) and glossy |

|

High abrasion resistance |

|

Excellent corrosion resistance |

|

Very good tarnish resistance |

Whether porous transport layers (PTL) and bipolar plates for hydrogen production, sensors in medical technology or contacts for plug connections - coatings with PLATUNA® PT are convincing in almost all technical fields of application.

Catalyst in electrolysers

In the hydrogen evolution reaction, platinum is used as a highly effective catalyst to accelerate the reaction at the cathode. It is more efficient and durable than other metals. It has a high activity for water splitting and is stable even at low temperatures, which reduces the amount of energy required for the reaction and thus enables the use of renewable energies (= green hydrogen).

PLATUNA® PT can be deposited directly on the ideal carrier material (titanium or nickel). Due to the excellent throwing power and the associated homogeneous distribution, the platinum layer can be reduced to a minimum (0.01 µm), which contributes to further cost optimisation of the process.

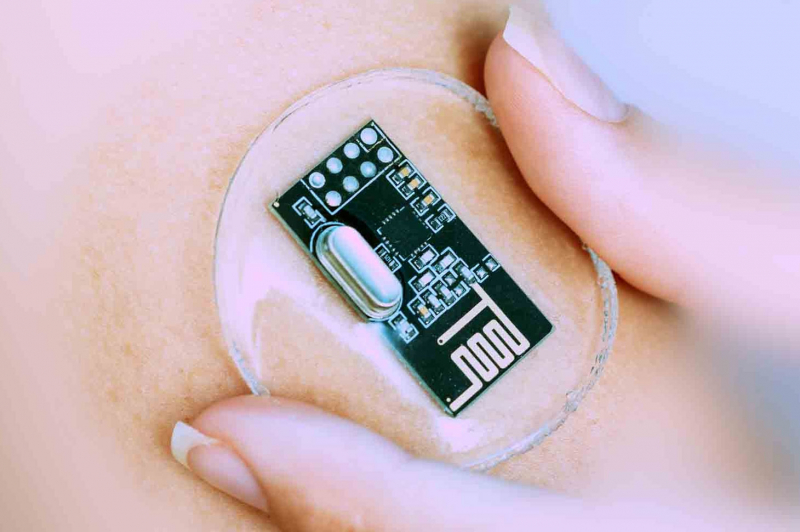

Sensor in the medical environment

Platinum is often used as an electrode material in medical sensors not only because of its excellent electrical conductivity. It is also biocompatible, i.e. it does not cause any adverse reactions when it comes into contact with living organisms, especially when the sensors are used inside the body. In addition, platinum is highly resistant to corrosion and wear, which contributes to a longer service life even under extreme conditions.

Whether as an electrode, catalyser or receptor in a medical environment: applications such as ECG, glucose, O2 and pH sensors benefit significantly from a coating with PLATUNA® PT.

Contacts in connectors

The PLATUNA® PT platinum coating can be used to reduce the contact resistance between electrical contacts and increase corrosion and abrasion resistance. The coating therefore helps to improve both performance and service life.

The advantages of a high-quality platinum coating are not only utilised in electronic devices for consumer electronics. Many industrial and automotive plug contacts also benefit from the increased service life in the long term. Maintenance cycles can be extended considerably in these segments and premature replacement of the contact systems can be prevented.

Platinum coatings are also used in a variety of other technical applications or industries - water purification or process control systems are just a few examples. Even very thin layers can improve performance, durability, efficiency and effectiveness or increase the sensitivity and accuracy of measurements.

The highly acidic electrolyte (pH value <1) itself is very easy to handle. The comparatively long shelf life and easy transport and storage make it possible to store large quantities and thus calculate costs with foresight.

During processing, the exceptionally wide current density range and insensitivity to higher electrolyte temperatures help to ensure very uniform deposition. Nevertheless, voltage-controlled work is possible. Low platinum contents do not affect the quality of the platinum layer at any time, only the coating speed (max. 0.13 µm/min at 3 ASD) is slowed down accordingly.

Advice and technical service right from the start

Are you interested in our PLATUNA® PT? Then let's talk about it. We offer you comprehensive advice in advance to clarify all the relevant details. We will be happy to provide you with a quotation on this basis. This should enable you to make an informed decision in favour of or against our solution.

Of course, we are also there for you after the successful implementation, even on site worldwide if required.

Markus Legeler

Manager Sales International

markus.legeler@eu.umicore.com

Start Teams Chat

+49 7171 607 204 (Office)

+49 170 9370 163 (Mobile)

LinkedIn | Xing

Website content matching this page